|

Sites like this can really

test the dowsers confidence, as well as skills. Especially

when the drillers say that there is no water at the predicted

levels that the dowser has quoted. Despite this, there was water

close to the predicted level. The pressure of the drillers

saying there was no water lasted several weeks before I could

prove that I was right and they were wrong. In certain

situations mud drilling does not always indicate correctly that

there is water there or not, especially when dealing with heavy

clays.

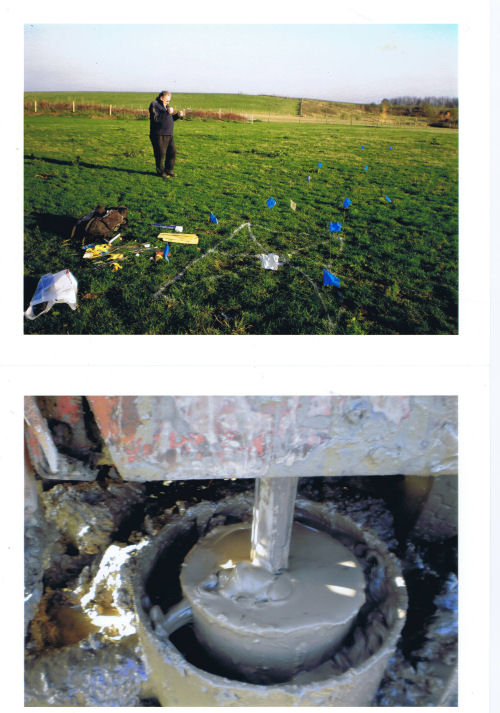

At the start of the job - This first photo -

indicates blue flags, the white spray paint indicates drilling

location.

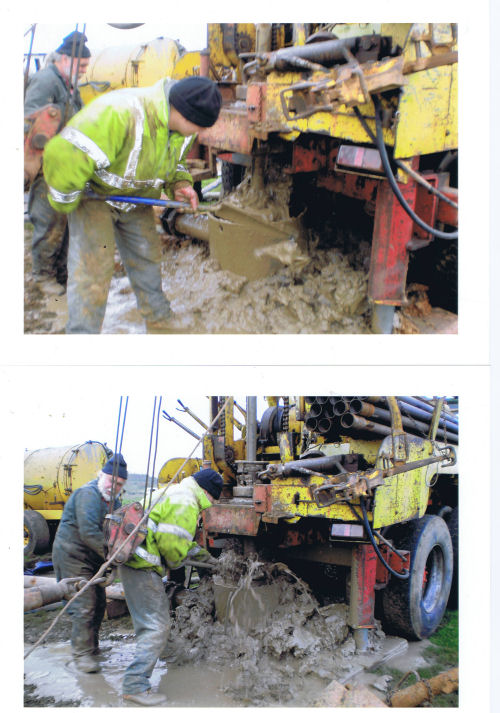

This second photo - shows clay and water. This is how the mud

drilling process takes place. Depth at that point was

approximately 30 meters of clay that we had gone through.

The above two photographs shows heavy, sticky

clay coming up with the water that the rig was using.The piping

system got clogged up twice in this process.

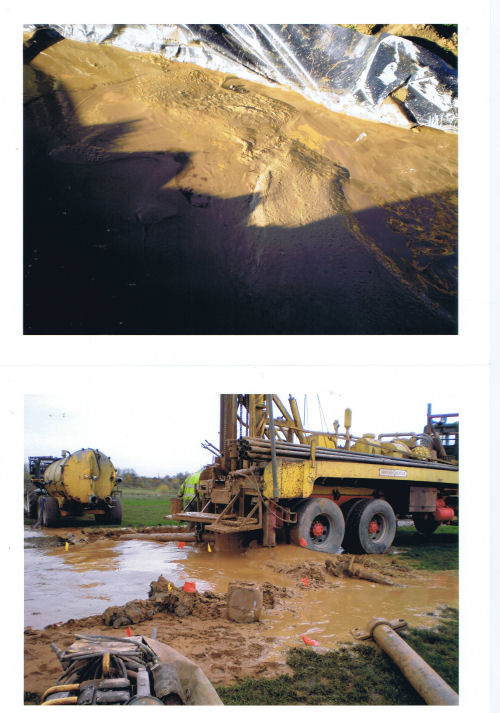

The photo below shows traces of oil floating on top of the mud

tank at 45 meters. We had gone through a series of clays and rocks

to this depth.

98 meters sand and water was hit. The mud drilling process at

that stage had sealed off a shallower source of water at 48

meters because of the heavy clays they had come across during

drilling. We also had come across shales and coal between the

levels of 50 meters down to 98 meters.

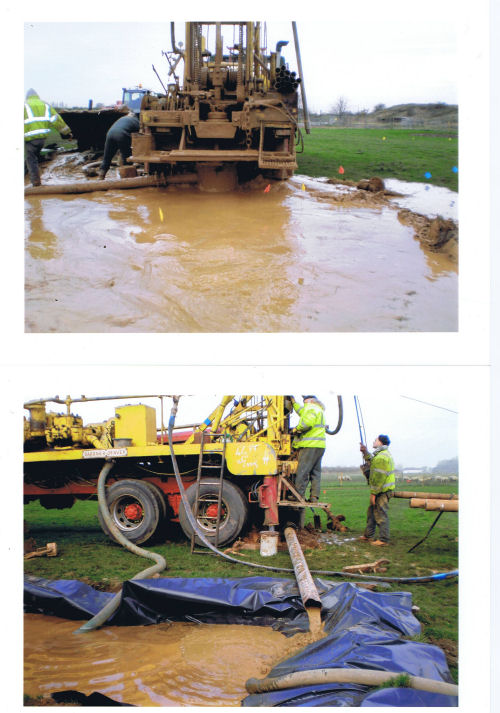

The

two photos below show the continuation of the water from the sand

at 98 meters to 100 meters, including the mud drilling water

also ......

welding of the steel casing and the water still being pumped up

The above two photographs shows the porous piping with sock on

going down into the bore hole of 120 meters. The next photo

shows the actual source of water produced from the bore hole

through the blue pipe into the tank.

At that stage it was not clean. The flow rate, after

tests was 700 gallons per hour. After pumping all day and all

night the flow rate was still 600 gallons per hour. Water in the

bore hole stayed steady at 56 - 57 meters beneath the ground.

By this time the water from 48 meters had managed to push

through the clay into the gravel surrounding the pipe.

This shows how clay can be a difficult substance to work with

for drillers and for dowsers.

This drilling process took place between December 2011 and

January 2012.

Further tests on the water quality is the next task to be

done...

The final chapter to the story which

has taken since the middle of November 2011 to the Middle of

April 2012 to be completed. The longest ever borehole I have

had to do but it was successful in the end in which they had

good drinking water. As you can see below...

Job

done.

The finished borehole, ready to be boxed in.

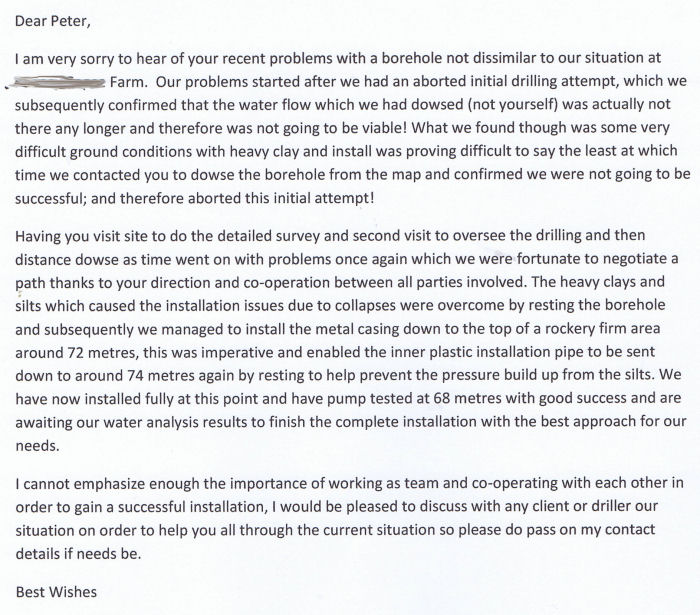

Here is the letter dated 14th January 2012 which outlines some of

the difficulties involved in drilling for water through clay...

|